- Print Studio Software

- Print Studio Autodesk Download Dremel

- Autodesk Print Studio Download Mac Installer

- Autodesk 3d Printing Software

Autodesk Print Studio is a Shareware software in the category Miscellaneous developed by Autodesk. The latest version of Autodesk Print Studio is 1.5.1, released on. It was initially added to our database on. Autodesk Print Studio runs on the following operating systems: Windows/Mac.

- Print studio free download - FotoSlate Photo Print Studio, Magix Xtreme Print Studio, Print Studio, and many more programs.

- Aug 17, 2018.

Print Studio Software

Ember is the DLP-based hardware that Autodesk is putting out there in response to the lack of open source hardware and software technologies available in the additive manufacturing or 3D printing realm. The software that has been popularized along with the Ember printer is Spark, the 3D printing platform. Just so we’re clear, Spark is not the software that actual works with Ember, i.e. it’s not the firmware. Let’s talk about all these things and more in detail.

First Off

“Designed by Autodesk, built in California” is the tagline for the new open-source 3D printing solution that Autodesk has put into the market. Just recently, Autodesk concluded that because of the numerous kinds of printers and accompanying proprietary software with them, the technology that was being used for everything from creating prosthetic limbs for children to developing mantle pieces just the same, is being limited and mandated because of the proprietary nature of the products.

To counter this constrictive approach to the technologies evolution, Autodesk brought its own solution claiming that such a platform could allow a more channelized and effective way of managing the technology, all the while standardizing the technology during its growth. Because of the design of the whole project, connectivity to the cloud, social media sites, and mobile apps are all possible to integrate and hence allow a much broader range of services through the combined application of these technologies.

What’s The Hype?

The Ember and Spark projects are so vast in their conception’s ideology as well as technological implementation, it’s a little difficult to begin talking about them. Hence in no random order let’s talk about a few premium features before going into the details.

The Ember printer is open-source, meaning you don’t need to actually buy anything. If you want to build your own 3D printer, just go to Autodesk’s A360 service online and download the 3D models for the printer. Then use a 3D printer to print the parts and build the machine yourself. Yeah, you read that right. You don’t need to buy anything, Autodesk actually allows you to take their design and build the thing for yourself. If you want to buy it, you can do that too. But even if you choose to print your own printer, the best part will be the standardization.

If you use Autodesk’s design and guidelines, your new printer will be able to work with Spark and other Autodesk’s standards. Even if you change the design somewhat, the Spark API allows you to hook up your new design with firmware custom-written for your design. Simple, flexible, completely customizable are just the starting features.

What’s more is that every single piece of equipment necessary, even the material is open-source. Meaning, you can download the specification of the material, and develop it yourself or get any of the materials available in the market if they are certified compatible with Ember. With this, the most intuitive and innovative features yet to have hit the additive manufacturing market are covered.

DLP vs. SLA

Print Studio Autodesk Download Dremel

In additive manufacturing, there exist two techniques outside the bounds of fused material printing. A liquid known as resin is a photopolymer reacts to light and solidifies. This resin is held in a tray that is lowered during the printing process. The light reflected collides with the resin and solidifies the model into an actual object. Just in case you’re wondering, the job is completed upside down.

This means the bottom of the model prints first. For both versions of the light-based printing, the source of light decides the technique to use. In pure Stereolithography (SLA), a laser is pointed at the resin to solidify the resin whereas in DLP (Digital Light Processing) a whole layer is projected into the resin to solidify the whole layer in a single go. This explanation will help you understand the basic need of the high powered light engine (fancy term for a projector) that allows such precise printing at such a good speed.

The Perks

As we saw before Ember can actually be printed by someone after having downloaded the 3D models from the website, it is noteworthy that the bragging rights for having printed your own 3D printer come at a cost. And that cost is more than the package that Autodesk give you by default.

Also, the projection equipment is state-of-the-art, custom built for this device so your version won’t be as top-of-the-line as the real thing. But that’s the idea behind Ember is for the average user to have the ability to play around with it and contribute to the development of this technology.

A Few Specs

In light of this, the default version of the Ember printer has a build volume of 64x40x134 mm (x, y, z) and can print layer thicknesses as thin as 10mm up to 100mm. The layer resolution is 50mm and the simultaneous printing mechanism prints more parts of the job together allowing for the least wastage of material and maximum time-cost efficacy. The projector that was custom designed for this device delivers over 1 million voxels per layer allowing up to 13.7 billion voxels for the total build volume. The projector uses a 405nm LED with a lifespan of 20,000 hours. The design is based on a TI authorized concept with all glass optics. The print speed is 18mm/h for 25µm layers.

The dimensions of the printer are 325x340x434mm with a weight of 10Kg. The operating temperature listed on the website is 18°C to 28°C. It can be connected to via Ethernet as well as Wi-Fi and USB options. The drivers for the hardware are available for Windows 7 and 8, with no notifications concerning Windows 10. Mac users can use it with OSX 10.9+. It allows printing with STL and OBJ files and hosts features such as mesh healing and procedural support.

Amongst the development perks of the Ember, Autodesk also claims to have engineered the mechanics in the most printing-friendly manner, with least amounts forces exerted on the model during the process allowing for fine detailed prints. The connected ecosystem available through A360 (Autodesk’s cloud service) and Spark allow jobs to be remotely regulated connecting the world’s resources together. The design, as noted before is clear and simple, with maintenance and replacement in mind.

Accessories

The parts and materials required to print in 3D are provided by Autodesk with all designs publicized. Any Resin that is certified the same way Autodesk’s resins are will work charms with the printer. Autodesk’s resins are available in a number of colors, with more finishes listed as “coming soon”. The Ember bundle from Autodesk includes the printer, 1 black and 1 transparent resin along with 2 build heads. 4 resin trays in total accompany the finishing kit.

Autodesk Print Studio Download Mac Installer

The finishing kit has the scrappers, a cutting mat, 50 nitrile gloves and glasses for safety during operation. Squeegees, watertight containers, and filters are included.

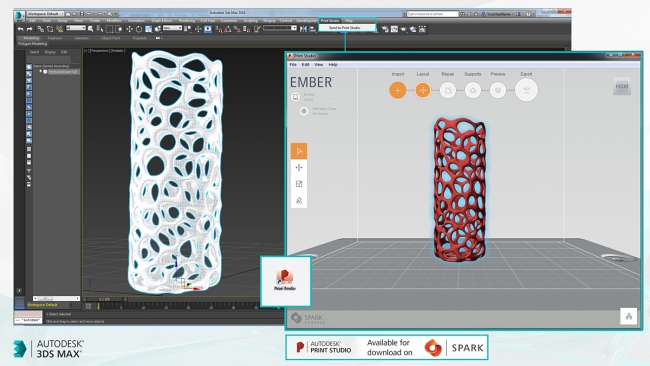

The Firmware

The software included with the printer, although you can write your own, is Autodesk’s Print Studio. And it’s Spark enabled. Everything that you need to review, design or print can be handled through the software and guess what, it’s obviously compatible with all Autodesk products. Both Windows and Mac versions are downloadable from the site.

Conclusion

Autodesk has finally taken its first step into the hardware market, albeit an open-source, free-for-all step. And it’s not a baby-step, just to be clear. Autodesk has a very clear vision and has capitalized on the opportunities they see in the evolution of such a powerful technology, coupled with their 20+years monopoly (of sorts) in the software market are making waves for the future of additive manufacturing.